+86 15968093247

+86 15968093247 Top 10 Sustainable Clothing Manufacturers in China

The top 10 sustainable clothing manufacturers in China for 2025 are Ningbo Dyon Industrial Group, Hongyu Apparel, China Eco Fiber, Appareify, Ninghow, Yiwu Ojj, Texhong Textile Group, Esquel Group, Luthai Textile Co., Ltd., and Shandong Ruyi Technology Group. This post details each, helping you make informed decisions. The market for sustainable clothing manufacturers in China is thriving. Experts project it will reach USD 68.4 billion in 2025.

Key Takeaways

- Sustainable clothing makers in China help the environment. They use good materials and treat workers fairly.

- China is a good place for sustainable clothing. It has new technology and makes things at a good price.

- Look for special labels like GOTS or OEKO-TEX. These show a company is truly sustainable.

Understanding Sustainable Clothing Manufacturing in China

What Defines a 'Sustainable' Clothing Manufacturer?

A sustainable clothing manufacturer focuses on minimizing environmental harm and maximizing social good. They prioritize ethical practices throughout their operations. Core principles guide these manufacturers:

- Resource Efficiency: They minimize energy and water consumption.

- Low Environmental Impact: They work to reduce their overall ecological footprint.

- Ethical Labor: They ensure fair wages and good working conditions for employees.

- Eco-Friendly Material Sourcing: They use materials like organic cotton, bamboo, hemp, and recycled fibers. They also maintain transparency in their supply chain.

- Responsible Production Processes: They use energy-efficient machinery and implement waste reduction strategies. This includes optimizing pattern layouts and reusing fabric offcuts. They also use chemical-free or low-impact dyeing methods.

The fashion industry contributes up to 8% of global greenhouse gas emissions. Every second, a garbage truck full of clothing goes to landfills or gets incinerated. Sustainable clothing manufacturers aim to stop these destructive practices. They design products for reuse and a longer lifespan.

Why Choose Sustainable Clothing Manufacturers in China?

China's manufacturing sector has shifted towards quality and sustainability. This is due to strict environmental standards and new technology. Choosing sustainable clothing manufacturers in China offers several benefits:

- Cost Efficiencies: Government policies foster green manufacturing. This leads to reduced waste and lower material costs.

- Advanced Capabilities: China has advanced manufacturing capabilities and economies of scale. This results in competitive production costs and efficient logistics.

- Eco-Friendly Focus: Manufacturers prioritize recycled materials and aim for zero-waste production. This meets consumer demand for sustainable products.

Key Certifications and Standards for Sustainable Clothing Manufacturers

Certifications help verify a manufacturer's commitment to sustainability. Here are some important ones:

- Global Organic Textile Standard (GOTS): This ensures organic status and social responsibility throughout the supply chain.

- OEKO-TEX Standard 100: This system checks textiles for harmful substances, ensuring product safety.

- Global Recycled Standard (GRS): This verifies recycled content and promotes responsible manufacturing.

- Responsible Wool Standard (RWS): This promotes ethical practices in wool production.

Ethical labor practices are also crucial. Standards include:

- Fair Wages: Workers receive pay that covers their basic living costs.

- Reasonable Working Hours: Overtime is limited, and workers get breaks to prevent exhaustion.

- Safe Working Conditions: Factories provide safety measures and protective gear. They also conduct inspections to prevent accidents.

- Absence of Child Labor: Manufacturers comply with labor laws and do not use child labor.

The Top 10 Sustainable Clothing Manufacturers in China for 2025

Ningbo Dyon Industrial Group

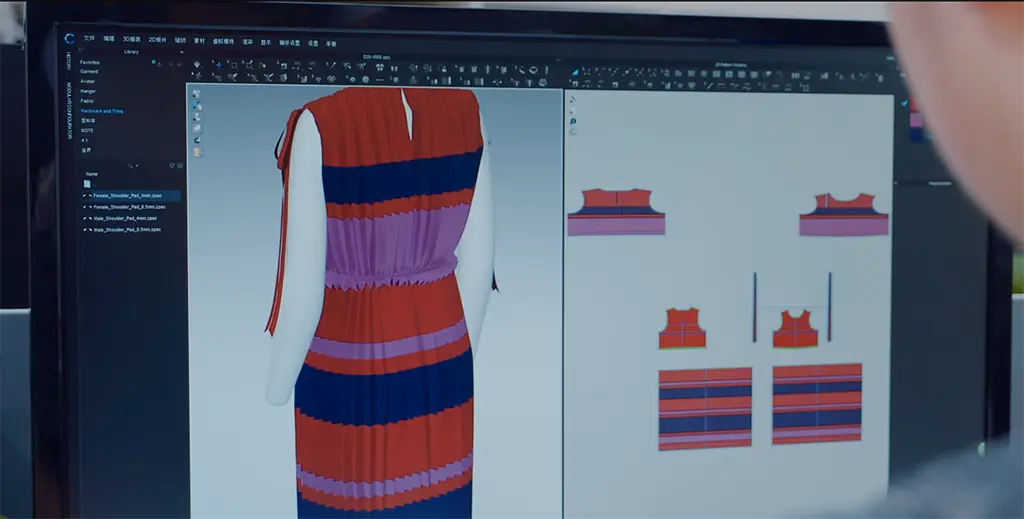

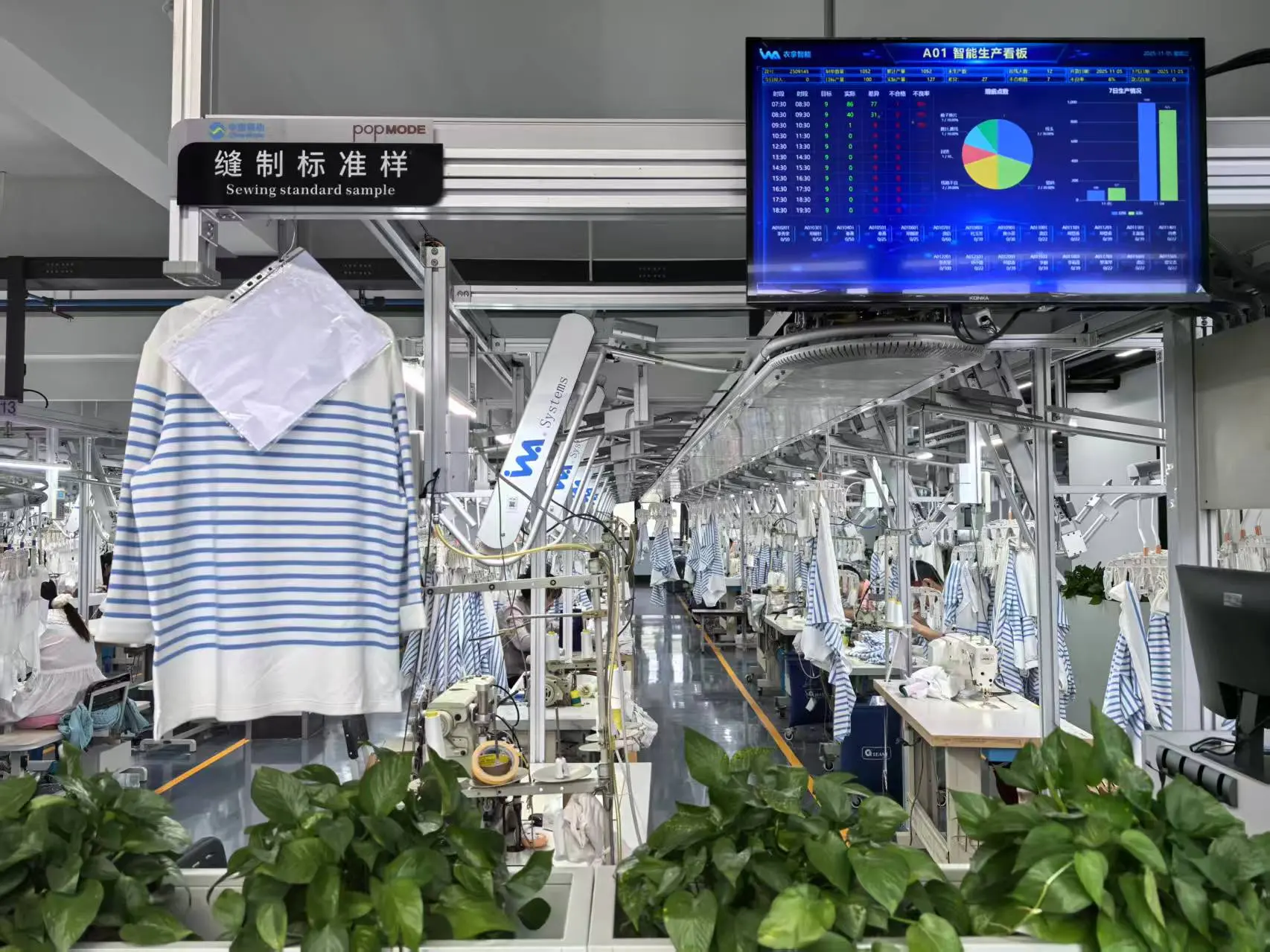

Ningbo Dyon Industrial Group, established in 1998, stands out as a one-stop clothing manufacturer. They specialize in high-quality fashionable wear. With over 25 years of experience, DYON provides complete solutions, from design and fabric sourcing to production and logistics. They believe everyone in the fashion industry should contribute to a better future. DYON works daily to make their fashion and company more sustainable.

DYON emphasizes its commitment to sustainability and eco-friendly practices. They recognize their importance to buyers and aim to make a positive impact in the industry. The company shows transparency in its operations. They separate trash for recycling and reduce paper use, printing on FSC certified paper. DYON produces eco-friendly products and uses fabrics with low environmental impact. These include Organic Cotton, Recycled Polyester, Ecovero Viscose, Lenzing Tencel, and Lenzing Modal. They actively investigate innovative materials like biodegradable fabrics. DYON also uses on-site bioremediation in printing facilities. This helps them reuse resources and lessen environmental impact. They focus on durable and resource-conserving fabrics. DYON continuously increases the proportion of natural or recycled fibers in its products. They support the Better Cotton Initiative (BCI) for sustainable cotton farming. DYON uses Ecovero™ viscose, made from sustainably grown wood. This process has 50% fewer emissions and water pollution than conventional viscose. They also incorporate Lenzing TENCEL™ from sustainable forestry and recycled wood waste. This uses a closed-loop manufacturing process. DYON uses Sorona® polymers, which contain 37% renewable plant-based ingredients. These consume 30% less energy and generate 50% fewer greenhouse gas emissions than nylon. They also utilize recycled polyester from existing cycles, like PET bottles, and employ recycled polyamide to reduce environmental pollution from disposal.

DYON holds important certifications. They are a supplier for products containing 55% GRS certified recycled polyester. Bureau Veritas also certifies their products, with certificate number TE-00063113.

Hongyu Apparel

Hongyu Apparel has earned its place among the top sustainable clothing manufacturers in China. They commit to responsible production and ethical practices. The company focuses on integrating eco-friendly materials and processes into its manufacturing. They strive to meet the growing demand for sustainable fashion globally. Hongyu Apparel works to minimize its environmental footprint while delivering high-quality garments.

China Eco Fiber

China Eco Fiber specializes in a wide range of eco-friendly materials. They consider the ethical and environmental impact of product creation and manufacturing. The company commits to less energy consumption, less water usage, and less waste. This helps them reduce their carbon footprint.

China Eco Fiber offers many sustainable material options:

- Organic Cotton

- Recycled Cotton

- Linen, Hemp, & Ramie

- Tencel & Modal

- Ecovero & Viscose

- Recycled Leather & Faux Leather

- Recycled Polyester & Recycled Nylon

- Bamboo Fiber

- Wool & Recycled Wool

For organic cotton, their materials offer significant benefits. They use no GMO seeds and help combat climate change. They preserve precious water resources and ensure fair prices for farmers. This promotes healthy farms and cleaner environments.

Here is a breakdown of their sustainable material categories:

| Category | Materials |

|---|---|

| Sustainable Planting | Organic cotton (GOTS), Raw Linen, Hemp |

| Recycle and Reuse | Recycled cotton, Recycled Poly, Recycled Leather |

| ECO Production | Tencel & Modal, Bamboo Fiber, Coffee Fiber |

Appareify

Appareify prioritizes sustainability by using Eco-Friendly Fabrics like organic cotton, hemp, and linen. They also employ a closed-loop system for plastic waste. This system ensures plastic items, worn-out carpets, and other recyclable materials are collected. Then, they regenerate these items by cleaning, sorting, liquefying, and reforming them. Next, they transform revitalized materials into small flakes, forging them into sturdy nylon 7 plastic chips. Finally, they convert these plastic chips into environmentally friendly, sustainable fabric using zero-carbon-emission manufacturing processes. This ethically crafts these earth-friendly fabrics into sustainable clothing, closing the loop.

Appareify also uses other sustainable technologies. They source solar energy for electricity and recycle industrial waste. They implement energy-efficient machinery and employ eco-friendly lighting. The company maintains high environmental and social standards throughout its operations. They diligently work to optimize processes and minimize waste. Appareify prioritizes ethical production practices. This reinforces their responsibility to the environment and the global community.

Ninghow

Ninghow is another key player among sustainable clothing manufacturers in China. They focus on integrating sustainable practices into their entire supply chain. The company works to source eco-friendly materials and implement efficient, low-impact production methods. Ninghow aims to provide high-quality garments while upholding strong environmental and social responsibilities.

Yiwu Ojj

Yiwu Ojj is noted for using eco-conscious materials, specifically organic cotton, in its products. They employ sustainable practices by utilizing eco-friendly materials and production methods. The brand prioritizes environmentally responsible practices, offering eco-conscious options to customers. Yiwu Ojj utilizes organic and recycled materials. Their products are certified by GOTS (Global Organic Textile Standard). The company focuses on sustainable sourcing practices.

Texhong Textile Group

Texhong Textile Group implements sustainable innovations across its manufacturing processes. They focus on eco-friendly raw materials, carbon emission management, energy-saving technologies, and the development of zero-carbon products and sustainable supply chains. The company integrates sustainability into procurement, transportation, production, and sales. They adhere to the 3R principles: Reduce, Reuse, Recycle. This includes sourcing natural sustainable fibers, regenerated fibers, and biodegradable fibers. They also employ energy-saving measures in both yarn and garment segments, such as photovoltaic power systems and optimized production processes. Furthermore, Texhong actively works to reduce the use of restricted chemicals like PFCs and formaldehyde.

Texhong uses a variety of sustainable materials:

| Type of Material | Percentage/Details |

|---|---|

| Cotton meeting sustainable plantation standards | Majority of cotton purchased meets standards; 21% CMIA/GOTS/OCS certified; 1.2% organic cotton (GOTS/OCS certified); 59% from Cotton LEADS approved US/Australian suppliers. |

| Viscose verified by FSC/PEFC | 8.2% of viscose procurement. |

| Recycled Polyester | 40% of total polyester purchases. |

| Natural sustainable fibers | Organic cotton (GOTS certified), Hemp, Linen (Hemp and organic cotton reduce carbon emissions by 45% compared to conventional cotton). |

| Renewable raw material fibers | Tencel (Cradle-to-Cradle certified, reduces water consumption by 95% compared to conventional cotton), Lenzing Refibra, Lenzing EcoVero, Sorona (PTT). |

| Regenerated fibers | Recycled cotton, recycled nylon, recycled spandex, recycled polyester (e.g., Repreve, Ecomade; reduces carbon emissions by 79% compared to virgin polyester). |

| Biodegradable fiber | Actively sourced. |

The company has undertaken several energy-saving and carbon reduction projects:

| Item | Commencement Date | Completion Date | Energy Saving/Carbon Reduction |

|---|---|---|---|

| Installation of MES energy monitoring system | October 2021 | June 2022 | Steam of 3,000 tonnes/year |

| Replacement of open water boxes | October 2021 | June 2022 | Steam of 8,000 tonnes/year |

| Use of wet mercerisation | October 2021 | June 2022 | Steam of 1,400 tonnes/year |

| Use of nitrogen for fire extinguishment (instead of steam) | January 2021 | July 2021 | Standard coal of 1,300 tonnes/year and reduction of CO2 emission of 3,458 tonnes/year |

| Energy-saving upgrade for continuous bleaching of knits | January 2021 | June 2021 | Standard coal of 330 tonnes/year and reduction of CO2 emission of 878 tonnes/year |

| Reducing power consumption per tonne of standard yarn | January 2021 | December 2021 | Power consumption in 2021 decreased from 2475 KWh/tonne in 2020 to 2450 KWh/tonne |

| Reducing annual steam consumption per tonne of standard yarn | January 2021 | December 2021 | Steam consumption in 2021 remained stable as compared to 2020 at 0.2 m3/tonne |

| Photovoltaic power system on factory roofs (yarn segment) | N/A | N/A | Approximately 146 million KWh wholly deployed in production process |

| Global distribution of production capacity | N/A | N/A | Reduces carbon emissions from transportation through local procurement and sales |

| Centralized procurement | N/A | N/A | Optimizes logistics and reduces transportation carbon emissions |

| Carbon footprint management teams | N/A | N/A | Monitor energy usage, environmental impact, set conservation targets, implement reduction projects |

| Cooperation with China National Textile and Apparel Council | N/A | N/A | Carbon emission measurement for key products (e.g., TENCEL) using LCA model |

| HIGG Index FEM 3.0 assessment | N/A | N/A | Assesses carbon emissions in garment fabrics and apparel segment for solution formulation |

Texhong also works to reduce harmful chemicals:

| Chemicals | Percentage as at March 2021 | Percentage as at June 2021 |

|---|---|---|

| PFCs Free hydrophile finishing material | 77.4% | 82.9% |

| PFCs | 22.6% | 17.1% |

| Formaldehyde-free resin for wrinkle-free finishing | N/A | Approximately 17% of wrinkle-free finishing auxiliaries in Vietnam factory replaced |

| Non-fluorinated chemicals | Began significant use since 2014 | N/A |

Texhong develops zero-carbon products. Since 2006, they have collaborated with suppliers to integrate environmental protection into products. They create green products with zero or low carbon footprints. They plan to build a professional production line for these products. Texhong's "Sustainable Procurement Policy" ensures sustainability principles are part of procurement decisions. They prioritize suppliers with outstanding sustainability performance. They encourage these suppliers to use clean energy, improve efficiency, use sustainable raw materials, and support certified carbon reduction projects. For example, a major regenerated cellulosic fiber supplier is SBT approved. This supplier aims for net-zero emissions by 2050. Texhong purchases zero-carbon products like Lyocell and MODAL fibers from them. Texhong also participates in environmental protection projects like Clean-by-design, Climate Roadmap, and Real Good of brands.

Esquel Group

Esquel Group shows a long-term commitment to sustainability. They view it as an inherent part of their business, even if it impacts short-term profits. Their Integral facility has achieved the LEED O+M Gold Award. This demonstrates their commitment to green building practices, energy efficiency, carbon reduction, and water resource management. They focus on sustainable operations and maintenance. Esquel collaborates across the value chain to share solutions and advance the industry. They participate in the Initiative for Sustainable Development Actions from Businesses alongside other leading companies. Esquel hosts the Integral Conversation conference annually to discuss sustainability. They focus on UN Sustainable Development Goals (SDG No.8 and No.12).

Esquel integrates sustainability into its core business strategy through its 5E-Culture: ethics, environment, exploration, excellence, and education. They have specific environmental efforts. These include reducing water and energy consumption (67% and 49% reduction respectively since 2005). They invest in wastewater treatment and develop methods to increase material utilization. They also use non-polluting natural dyes. Esquel emphasizes a 'people-plus-technology approach'. They prioritize employee transformation, training, and creating knowledge-based job tasks. They established the Esquel Sustainability Council in 2013. They also became the first textile and apparel supplier accredited by the Fair Labor Association. Esquel operates with a sustainability framework based on four strategic pillars: people, planet, product, and community.

Luthai Textile Co., Ltd.

Luthai Textile Co., Ltd. expresses clear goals in all four key areas of corporate sustainability, including environmental protection. This classification comes from the company's statements. These statements indicate what they have done or intend to do regarding sustainability. Luthai Textile actively works to implement eco-friendly measures throughout its operations.

Shandong Ruyi Technology Group

Shandong Ruyi Technology Group dedicates itself to textile innovation. They focus specifically on high-tech materials and environmentally friendly production methods. This group is a prominent entity in China's bio-textile industry. They actively incorporate eco-friendly fibers into their large-scale production. They also collaborate with international brands. Shandong Ruyi Technology Group continually seeks new ways to produce textiles with less environmental impact.

How to Choose the Right Sustainable Clothing Manufacturer for Your Brand

Assessing Your Brand's Needs and Values

Choosing the right partner starts with understanding your brand. First, assess your company's current environmental impact. Look at raw material usage, energy consumption, and waste management. Then, define clear sustainability goals. These might include reducing waste or using more sustainable materials. Ensure everyone in your organization commits to these goals. Ethical sourcing is also key. This means getting raw materials that respect the environment and ensure fair labor. Integrate sustainability deeply into your brand's values and daily operations. Remember, consumers, especially younger generations, look for authentic and transparent actions. Your brand's values should guide your sourcing strategy. Create teams that combine sustainability and sourcing. This ensures environmental and social impact becomes a core part of supplier evaluation.

Evaluating Manufacturer Transparency and Verification

You need to verify a manufacturer's claims. Look for third-party certifications like ISO 14001 or B Corp. These show a commitment to environmental management and social performance. Conduct thorough research on a supplier's history. Ask for detailed documents like audit reports. Site visits can also help you observe their operations directly. A transparent manufacturer willingly shares critical supply chain information. They also make ESG (Environmental, Social, and Governance) data publicly available. Be careful of greenwashing. This happens when companies make vague claims or hide negative impacts. Always check for reputable certifications and measurable goals.

Questions to Ask Potential Partners

When you talk to potential partners, ask specific questions. This helps you find the best fit.

- Environmental Policies:

- What is the origin of your raw materials?

- How do you handle production waste?

- Which environmental certifications does your facility hold?

- What percentage of your energy comes from renewable sources?

- Labor Practices:

- How do you ensure workers are above the legal working age?

- Do you respect employees' rights to collective bargaining?

- How do you prevent discrimination in hiring and promotion?

- Do workers receive fair wages and appropriate rest breaks?

- Material Sourcing and Waste Management:

- Do your fabrics have eco-certifications like GOTS or OEKO-TEX?

- What percentage of your materials are recycled?

- How do you manage waste, such as fabric scraps and water?

- Are your products designed for recyclability or biodegradability?

Asking these questions helps you find Sustainable Clothing Manufacturers that truly align with your brand's vision.

Selecting a sustainable clothing manufacturer in China requires careful consideration. Look at their practices, certifications, and how they align with your brand's values. The listed manufacturers offer diverse sustainable solutions. They provide a strong foundation for ethical and environmentally responsible production in 2025.

FAQ

What makes a clothing manufacturer sustainable?

A sustainable manufacturer minimizes environmental harm. They use eco-friendly materials and ethical labor. They also reduce waste and conserve resources.

Why should brands choose sustainable manufacturers in China?

China offers advanced capabilities and cost efficiencies. Manufacturers prioritize eco-friendly materials and zero-waste production. This meets global demand for sustainable products.

Which certifications prove a manufacturer is sustainable?

Look for GOTS, OEKO-TEX Standard 100, GRS, and RWS. These certifications verify environmental and social responsibility.